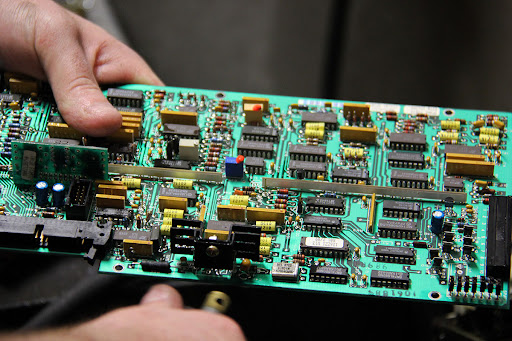

Automated optical inspection or AOI is a technique that is primarily used in the testing and manufacture of electronic printed circuit boards (PCB). This way allows for accurate and fast inspection of electronic assemblies, especially PCBs, to ensure that the quality of the product which is leaving the production line is good and the items are built properly without any manufacturing defects.

If you are an electrical appliance manufacturing company and are thinking of buying an AOI system, you should check out the automated optical inspection system Malaysia. The company MTSC solution manufactures automated process solutions, both test, and inspection system devices and many others which you will need for a smooth production process.

Why is there a need for AOI?

Despite the improvements, the manufacturing of modern circuits is much more complicated than boards. With introduction of the surface mount technology and reduction in sizes, the circuits have become very compact. Even the average circuit would have at least 1000 solder joints. This is where most problems are found.

The complexity increase in the case of boards also means that manual inspection is not possible anymore. This is why AOI has become an integral part of the electronic testing strategy.

Once the AOI tests the PCB circuit boards, the ones who pass the test move forward in the production line. The ones who do not pass the test are sent back to be rectified.

Is AOI the only method to measure PCB viability?

No. There is one more way in which you can measure PCB viability. You can use LCR meters for this purpose. An LCR meter is an electronic test equipment that specifically measures the capacitance, resistance as well as the inductance of the electronic appliance. In simpler versions of LCR meters, only the impedance was measured internally. This impedance was then converted to the inductance and capacitance value for display.

The device that is under test is first subjected to an AC voltage source. The LCR meter measures the voltage and the current passing through the device and the test. From this ratio, the meter determines the magnitude of impedance. The phase angle between the current and voltage is measured in more advanced instruments. This is done in combination with the impedance.

An LCR meter can also measure the inductance variation with respect to rotor position in the case of permanent magnet machines. Handheld meters have selectable frequencies of 100 Hz, 1 kHz, 10 kHz and go all the way up to 100 kHz. The measurement range capability and the display resolution changes with a change in the test frequency.

If you want to get an LCR meter for your company, check out LCR meters Malaysia. As I mentioned before, MTSC excels in the production of testing equipment. They are one of the best solution providers in the South Asia Pacific region. Their customer service and support coverage is simply excellent. You cannot go wrong if you decide to go with this company.