A PTO, otherwise known as power take-off, is basically any of several methods that can be used to take power from a power source, say a running engine, and transmit it to an application such as an attached implement or separate machine. In other words, it is a device that transfers an engine mechanical power to another piece of equipment. It allows a hosting energy source to transmit its power to a machine that doesn’t have its engine or motor, for example, a jackhammer running on a tractor engine or a splined drive shaft installed on a tractor or truck to allow implements with mating fittings to be powered directly by the engine.

Types Of PTO

Air Power Take-Offs come in various kinds, but the common ones are Mechanical and Hydraulic. A mechanical-independent PTO will use a separate on-off selector, alongside the PTO control lever. More often than not, the tractor must be stopped or off for one to be able to change this selector position. The main difference between the two is that a hydraulic-independent PTO will only use a single selector.

Other types of PTOs include;

Pilotless Mechanical PTO

The distinguishing characteristic of this PTO is the designed removal of the pilot bearing. This design feature comes with a few design benefits, including increased side load capacity, increased uptime and engine life, reduced inventory, and a quicker and easier installation process. Some of the Industrial uses of the Pilotless Mechanical PTO include; Chippers, Asphalt grinders, Irrigation pumps, and water blasters, among others.

Type 1 PTO

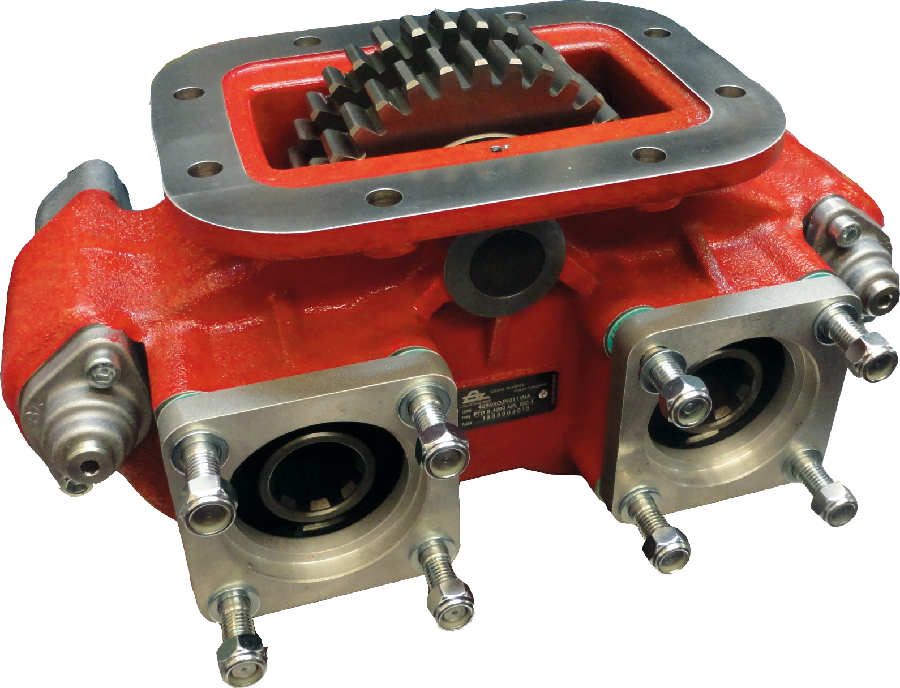

This is a rugged, high-capacity type of PTO which is used in a broad range of industrial functions. A significant attribute of this type of PTO is the sheaves between heavy-duty spherical roller bearings which are designed to utilize their full load potential. This bearing arrangement is aimed at reducing the damage produced by crankshaft loading. Some of the most common uses for the Type 1 PTO are in mud pumps, dredges and rock crushers.

Type 2 PTO

This PTO has a design that features a heavy-duty side loading capacity that uses sizable spherical roller bearings. Actuation of this PTO can be either hydraulic or pneumatic. It stands out because it is self-adjusting and eliminates the need for the pilot bearing inside the engine flywheel. Prominent features of type 2 include reduced maintenance, a lesser chance of premature failures, and improved engine and bearing life since the crankshaft isn’t directly loaded. Its applications include road-building equipment, portable rock crushers and tub grinders.

Pilot Over-The -Shaft PTO

Unlike any other air power take-offs, this one erases any need for the pilot bearing, just like the name suggests while providing increased side loading or inline potential. The way it is designed accommodates the most demanding requirements of high-loading diesel engines. With this, you get the benefit of reduced downtime, simple installation, and improved engine service life. This style PTO is used for in-line applications since the hydraulic and air fittings are mounted near the bell housing rather than at the rear of the shaft like type 1 and type 2.