The operating cycle of a water cooled chiller assumes constant maintenance of a reduced condenser temperature, where the vaporous freon again turns into a liquid state. Today, chillers use two cooling schemes – air and water. Each of them has its own characteristics, advantages, and disadvantages. This article will consider the principle of operation of a water-cooled chiller with its inherent specifics.

Water-cooled Chiller Device

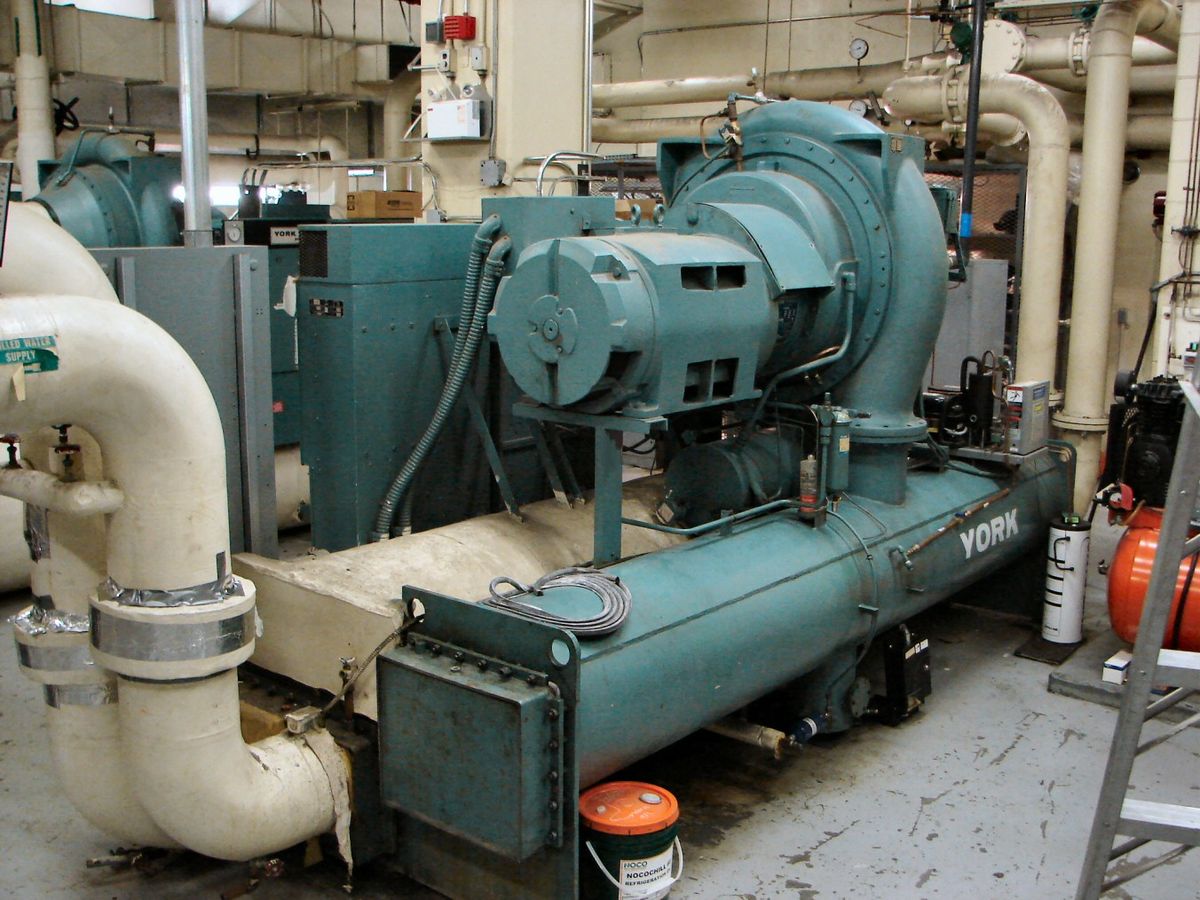

Before considering the principle of operation of a water chiller, it is necessary to understand the approximate design diagram of such installations. In general, it consists of the following elements:

- compressor – this element provides the necessary pressure sufficient to compress the gaseous freon to a high (about 90⁰s) temperature;

- condenser – in this part, the compressed refrigerant gives off heat and condenses, turning into a liquid state, for which a cooling system is needed;

- evaporator – the function of this part is heat exchange between the cooled freon and the coolant (water or ethylene glycol), separated by a sealed partition.

Thus, any chiller must have a cooling system in order to provide the refrigerant at a reduced temperature. It is made before it is fed to the evaporator, where it boils, taking heat from the coolant.

Working Schemes

The water cooling the condenser, in turn, must give off the accumulated heat. To do this, it is supplied to additional modules, which are a heat exchanger between it and air. Two types of these devices are used in water-cooled chillers:

- cooling towers – the water heated in the condenser is sprayed through nozzles and contacts the air, giving off heat to it and re-entering the condenser.

- dry coolers – such devices are a surface heat exchanger between water and air, blown by axial fans.

The first option for water cooling in chillers appeared earlier. It is characterized by a complex design, the need for careful and regular maintenance.