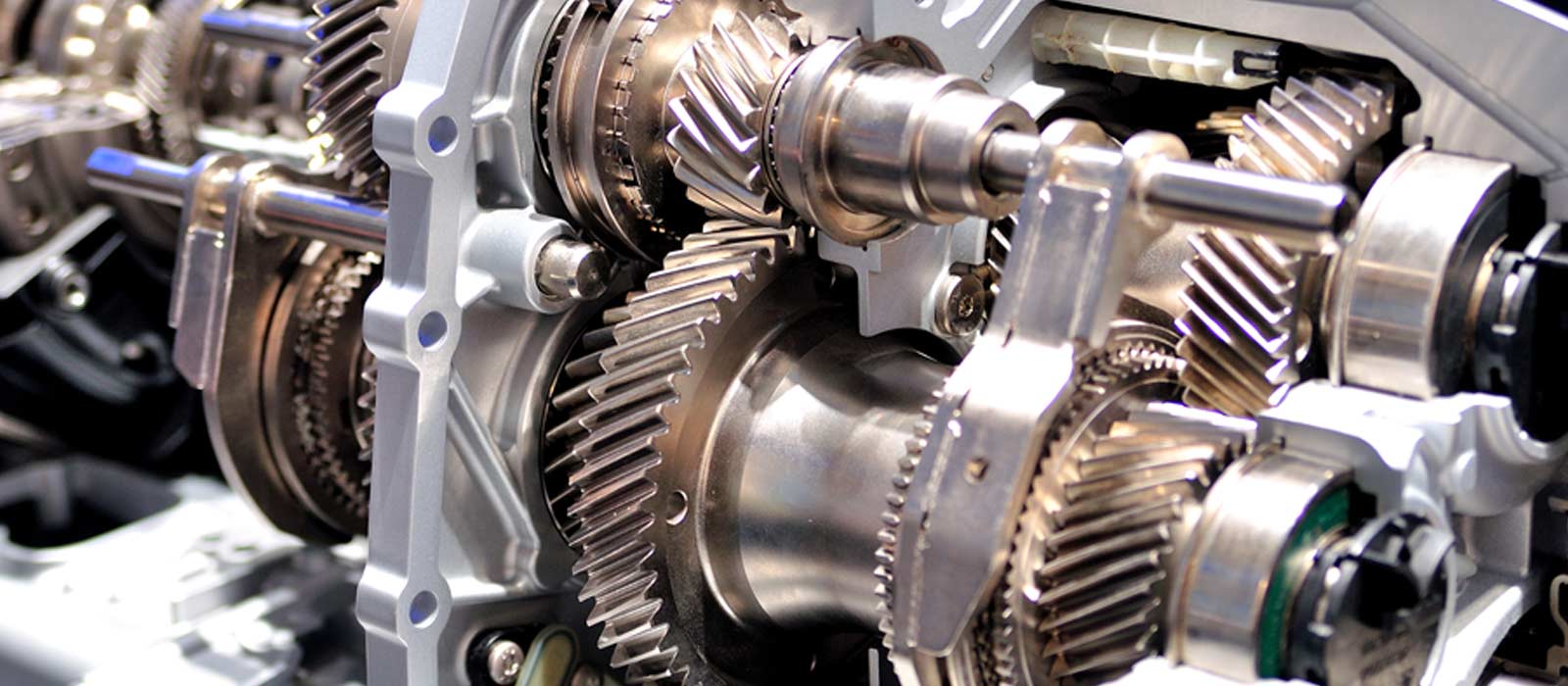

Many different types of gearboxes are used in different industries. Some gearboxes are used for simple applications and are very robust, such as the gearbox used in a bicycle or a lawnmower. However, some gearboxes are used in more complicated machinery such as the gearbox used in an industrial machine, or a spacecraft. These types of gearboxes are also known as rotating speed-reduction gears.

Industrial gearboxes are robust equipment that can take on extreme temperatures, pressures, and abrasive environments. However, their lengthy lives dissuade many owners from conducting regular upkeep. Failing to react to minor issues could have consequences that reach past just your equipment. Your industrial gearbox, like any other equipment, will alert you if there are problems that have to be addressed.

Noise

A faulty gear unit may commonly begin to emit noises. These noises may be due to the internal parts rubbing against each other. Bearings, gears, and shafts wear out as time progresses, and as they do, they generate more irritating noises.

It is recommended to check your gearbox if you notice that the noise is getting louder. Proficient mechanics may utilize audio intensity to pinpoint the source of the drawback. Defective motor mounts often cause unusual sounds, such as clicking and clunking noises, whereas damaged or missing teeth can cause high-pitched screeching sounds.

Overheating

Is a substantial temperature differentiation between your housing and the spindle of industrial equipment indicative of a malfunction? This might mean that the fact that something is not being run as it should be.

- The smoke emitted by shafts and seals

- The discolouration of surfaces caused by burning

- The melting of plastic parts

…are symptoms of overheated gears. Lubrication isn’t functioning properly. It should improve daily life by lowering friction and cooling. If that’s not happening, overly aggressive bearings may be causing excessive friction and heat.

Cracks

If there is a discrepancy between the intended speed and torque of your gearbox or if you notice damage to the unit, you should inspect it quickly. This could be due to vibrations caused by the unit’s high-speed or high-torque operation. Components that are loose, damaged, or improperly installed can vibrate violently, eventually damaging other parts of your equipment or moving out of place.

Misalignment

Parts will gradually become displaced and relocate out of their original place over time. Wear and tear, vibration, and heat transmission can all be factors. Nevertheless, the root of the problem might already have originated at the time of mounting. If it is not possible to procure the appropriate conveyor belt, it will likely malfunction later. Similarly, if it isn’t correctly installed, it may fail prematurely.

Oil Spills

Examine your gas tank’s shaft seals. You have an issue if you see oil dripping out. If the seals fail, oil drips out, allowing dirt, water, and dust to enter. Check your oil levels even if you don’t notice there’s an oil leak. If they are suspiciously low, you may want to look elsewhere for an oil spill. An oil spill can also be caused by faulty gaskets.

Keep Your Gearbox in Check With Premium Transmission

If you allow transmission problems to go unresolved, they can cause your production process to come to a complete halt. That is why it’s always crucial to conduct regular check-ups and maintenance of your gear.

Perform regular inspections, and you may quickly eliminate the glitch in your machine or gear. Additionally, guaranteeing that your equipment is made using quality materials will assist its functionality.

Conclusion

An industrial gearbox is a mechanical device used to transmit power from a prime mover (usually an engine) to some other machine or device. Though it is often used to transmit motion between the two shafts of a machine, it is sometimes used to power just one of them, as in a car gearbox. Every gearbox has several parts; some of the most important parts are the shafts, gears, and bearings.